With rigid testing procedures, uncompromising quality standards, and meaningful reports, White Horse Laboratories helps secure supply chains in the electronics industry.

Early detection and prevention of counterfeits determines the quality of the entire supply chain. We develop a customized risk mitigation plan and perform everything from screening third-party samples to creating a database of “known good parts“ to high quality inspection standards such as AS6081, AS6171, AS5553, CCAP-101, and IDEA-1010.

- Documentation and Packaging Inspection

- External Visual Inspection

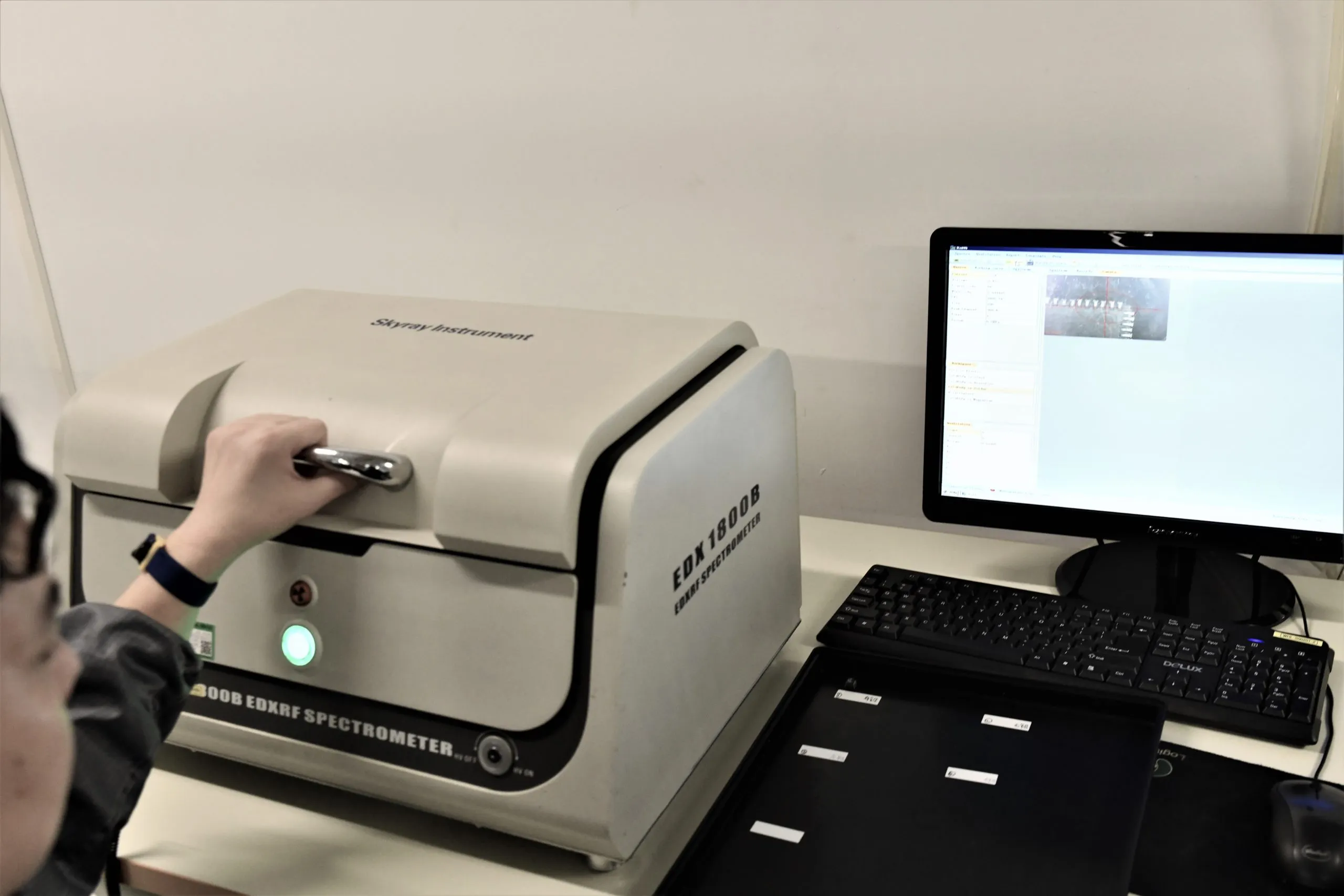

- X-ray Fluorescence (XRF)

- X-ray Analysis

- Heated Solvent Test

- Decapsulation and Die Analysis

- Electrical Test

Failure analysis of electronic parts and components provides meaningful information about why they do not meet performance expectations, but also about their potential performance in their intended end use. Conducting an unbiased failure analysis by an independent testing laboratory ultimately enables the manufacture of higher quality products.

- Scanning Electron Microscopy (SEM)

- Energy Dispersive X-ray Spectrometry (EDX)

- Scanning Accoustic Microscopy (SAM)

- Cross-section (Microsection)

- Parallel Lap

- Hot Spot Test

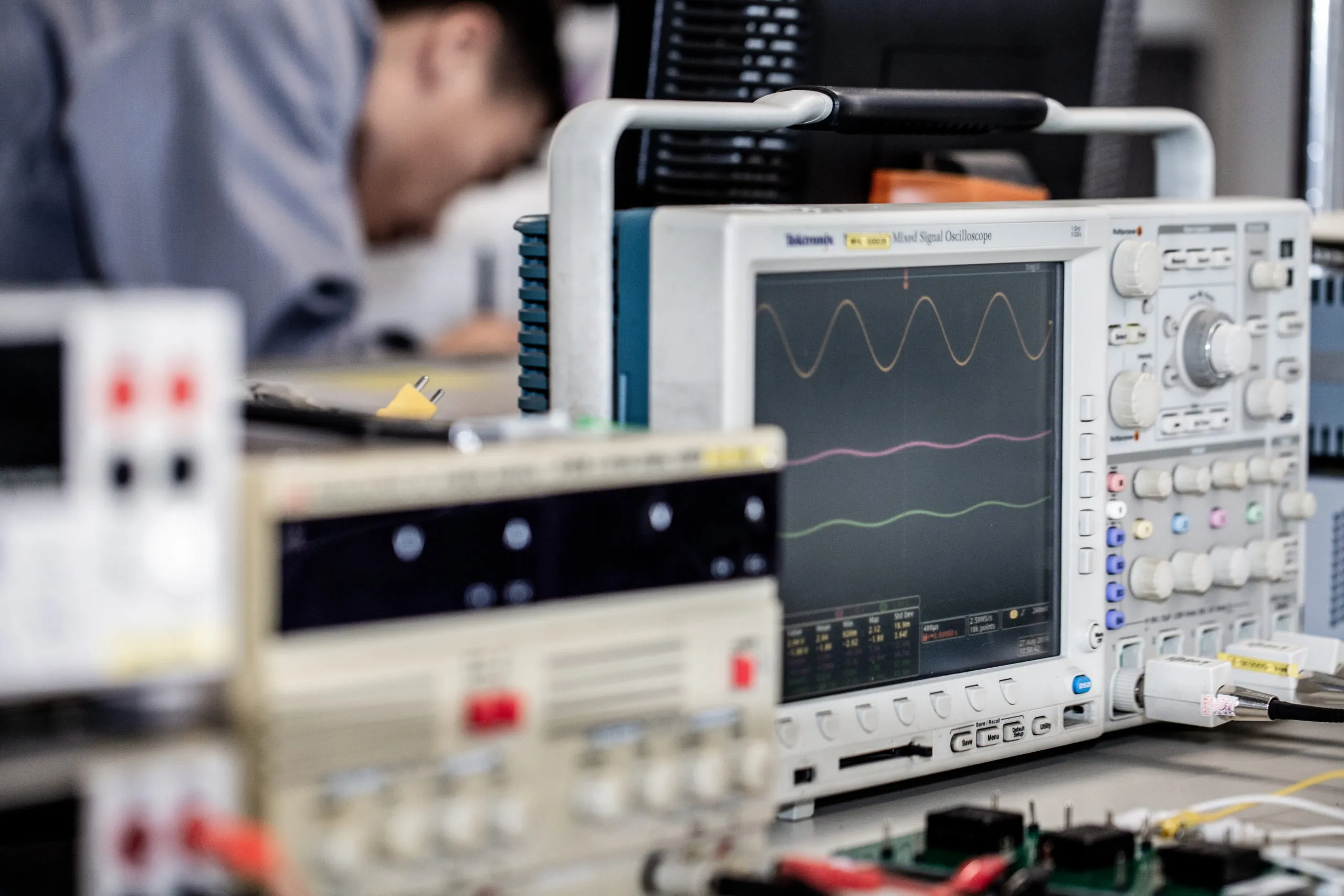

- Electrical Test

To make predictions about a product’s longevity based on its characteristics, lifecycle testing analyzes how the product functions under normal conditions of use. To simulate intensive use as well, reliability testing exposes products to extreme conditions that far exceed normal operating requirements.

- Thermal Cycle

- Thermal Shock

- Burn-in

- Drop Test

- Vibration Test

- Environmental Exposure (Temperature And Humidity)

- Salt Spray Test

- Electrical Overstress Testing

- Mechanical Stress Testing

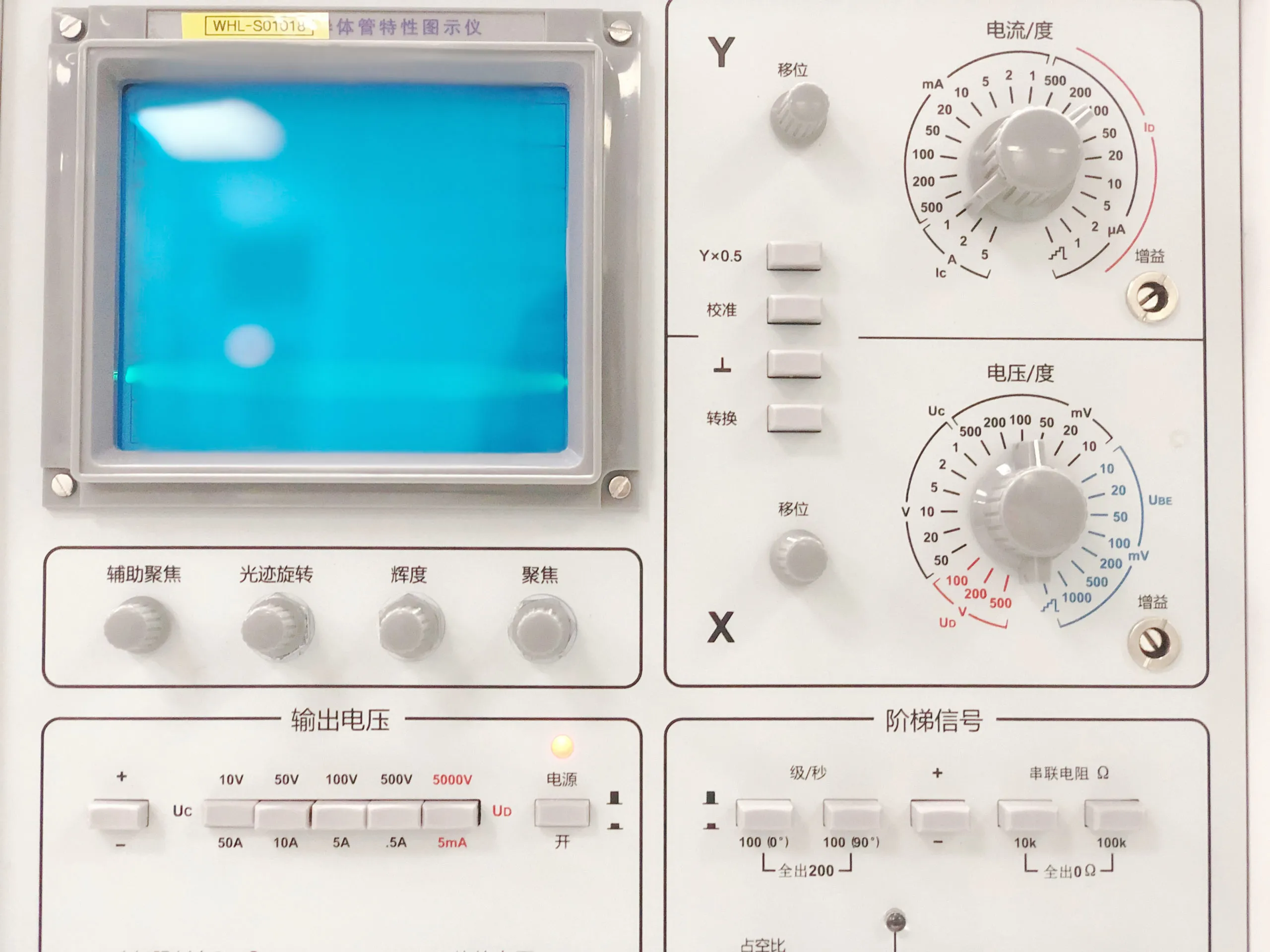

The tests we perform consist of six increasing levels, depending on the device being tested and the tests required by the customer. Our scope ranges from verifying performance, speed, durability and reliability of components to detecting defects and faults.

- Curve Trace

- Pin Verification Test

- Functional Test (Primary)

- DC Characteristics

- AC Characteristics

- Temperature Range Testing